WHAT’S NEW?

What’s new on Hydro-Dyn press?

The motor behind Dr. Haupt’s R&D activities are the demand of Hydro-Dyn press users for

- improved product quality

- reduction of operational costs

- increase in line capacity

- increasing stability of press operation

Particular emphasis in recent years was placed on the following areas:

1 Scraper pads in the press out-feed

Scraping silicone oil from the steel belt in the press out-feed leads to a good contact of the steel belt to the press drum. This situation is improved by the use of special scraper pads in the press out-feed. Efficient oil scraping could be proven by V-shape scrapers.

4 Avoiding or reducing leak flow under the pads

Development activities of particular importance were accomplished in work on leak flow in the press between heating platen and Al-plates with the Teflon pads.

This leak flow reduces the heat transfer in the press and consequently the efficiency of the machine.

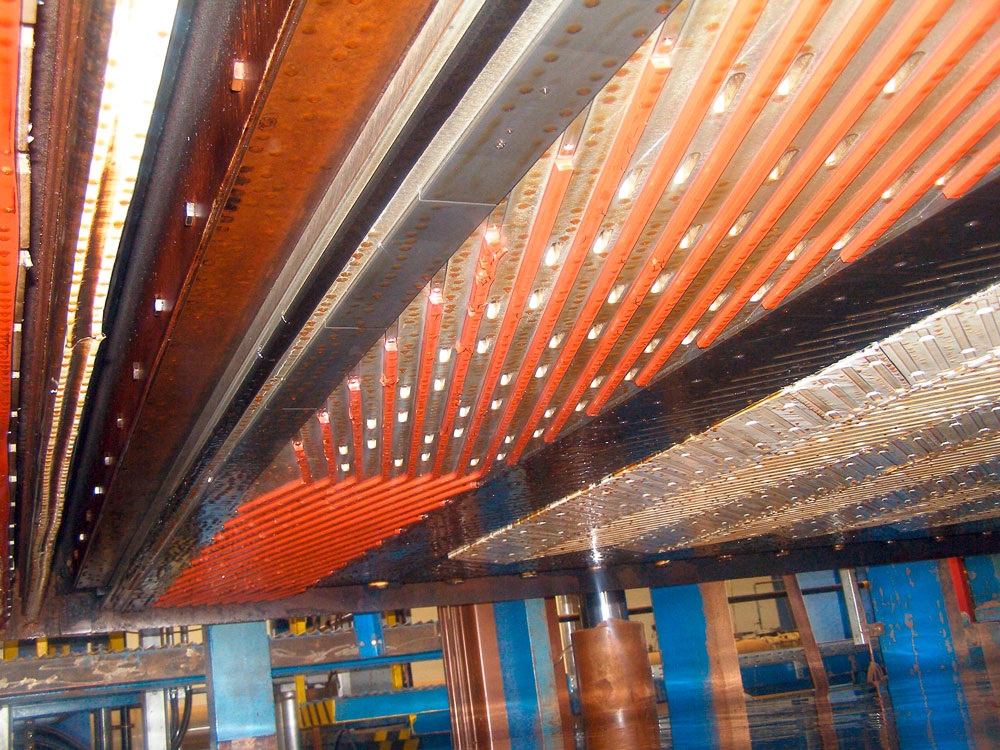

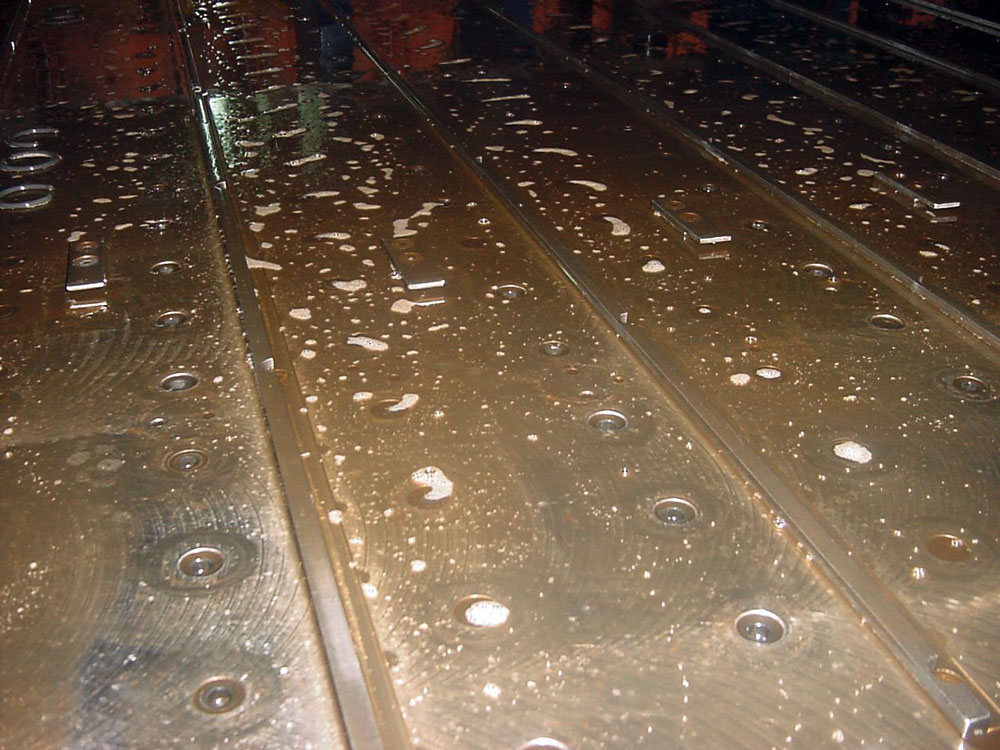

A significant layer of silicone oil is usually found on the lower heating platen (see photo).

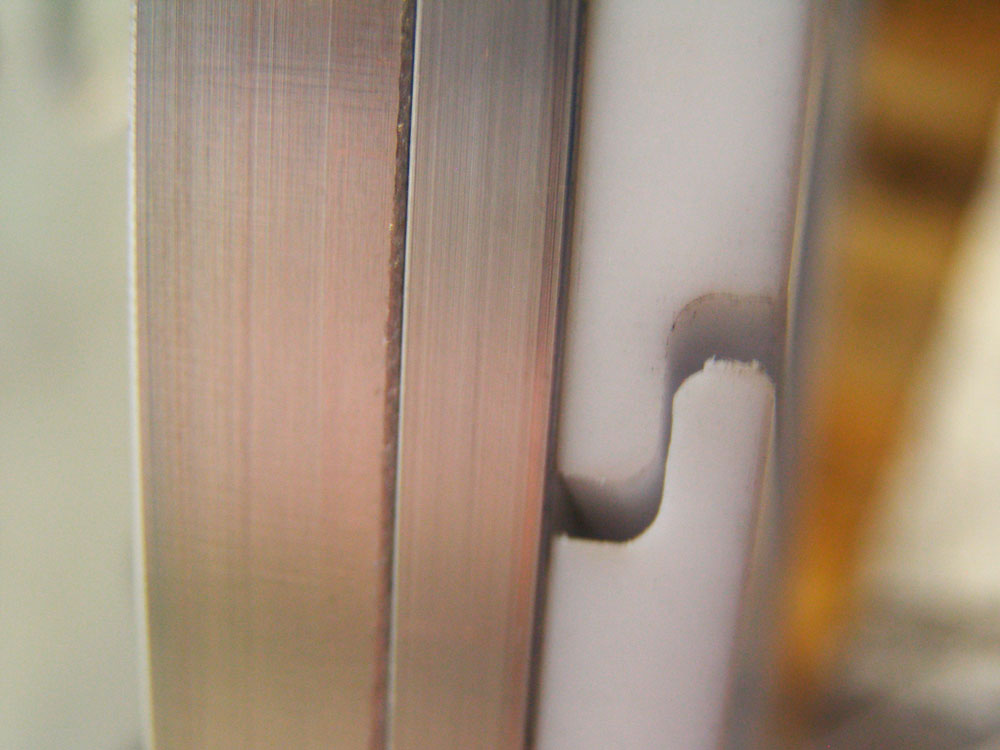

O-rings seal the gap between heating platen and Al-plates – but they are wear parts and loose their efficiency by and by (see photo O-rings).

2 O-rings in one groove were occasionally found in presses (see photo). A suction force from the flow between heating platen nozzle and Al-nozzle was assumed.

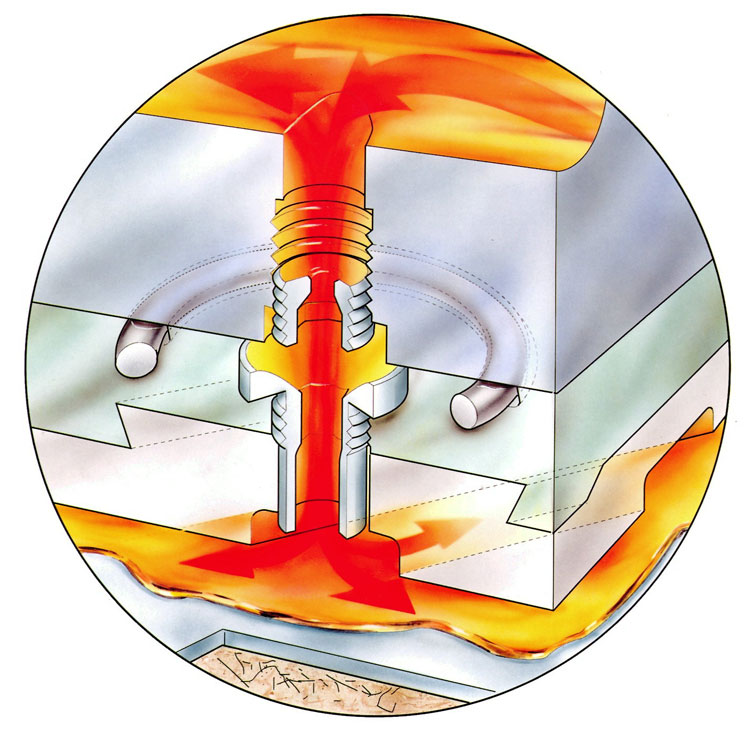

The suction effect was confirmed in a fundamental test with air (see photo).

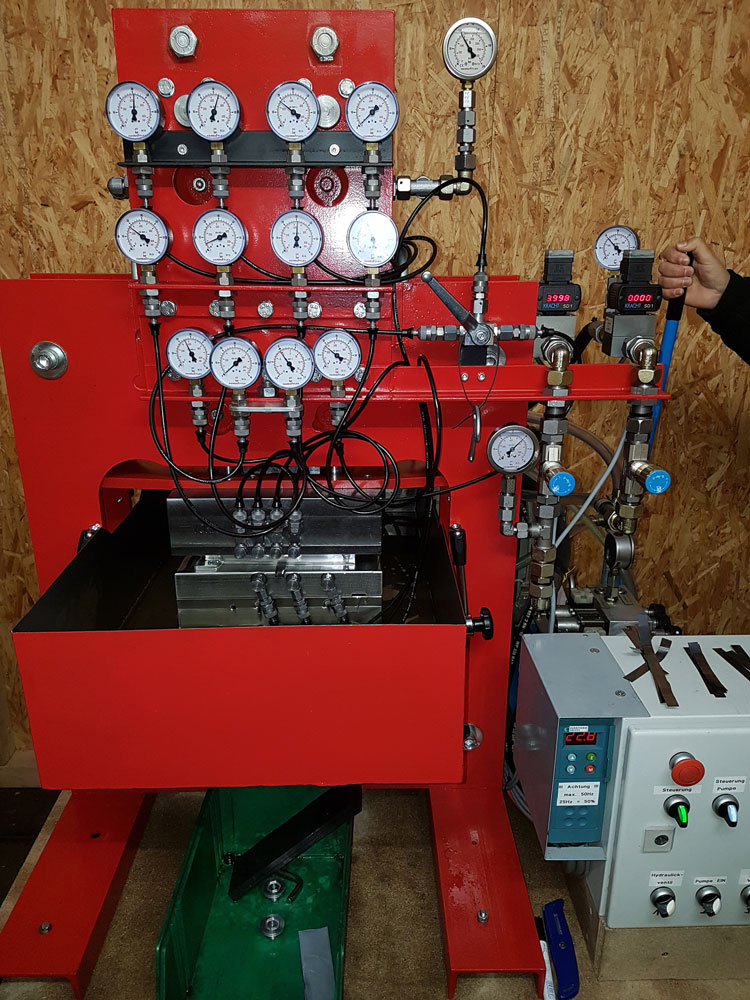

Another test rig was manufactured working with hydraulic oil. Test on this rig proved the existence of a deep vacuum in the flow passage (see photo).

Further tests were done on a new test rig with pressure measurements around a Teflon pad (see photo below).

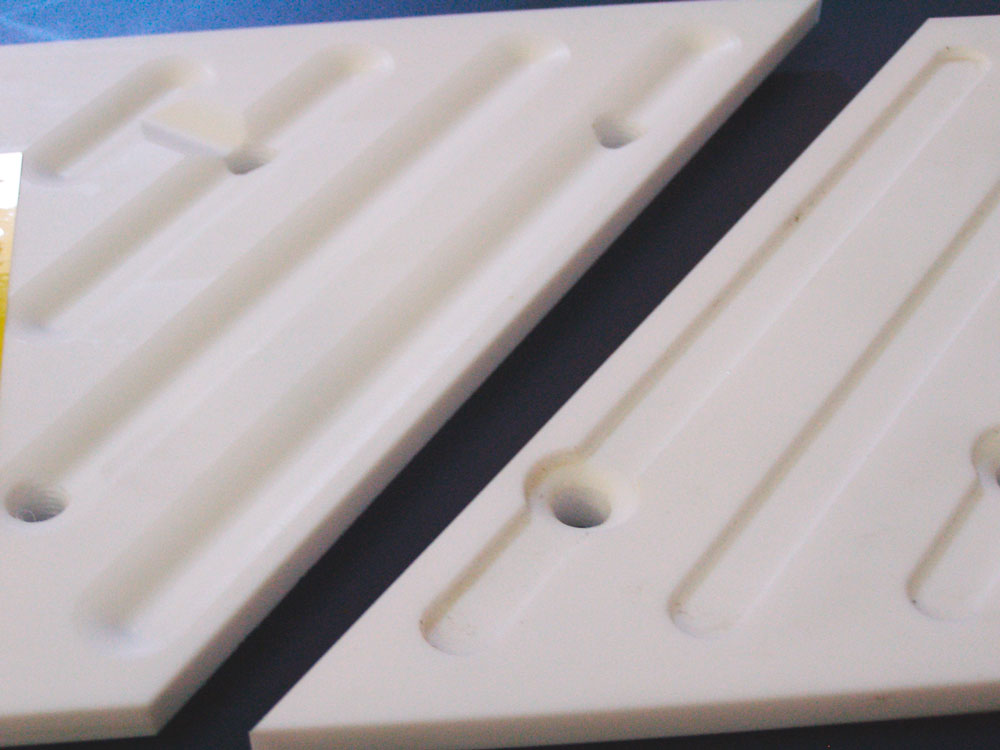

Based on these findings a complete new generation of Al-plates with Teflon pads was created. Complete presses were equipped with these pads and showed surprising and spectacular results. Pressure and temperature measurements in 2 production presses were accomplished, confirming the positive behaviour, more uniform oil flow in the surface and a better heat transfer in the machine.

Dr. Haupt will provide more details about this development upon request.

5 Modifying Teflon edge pads toward better product edge quality

Product edge quality has always been an issue in the R&D activities on Hydro-Dyn presses. A weak point in the design of the Teflon pads in the edge zone could be found and a new design was created.

This progress is still fresh and waits for a confirmation by the use of this technique in a production press.

Dr. Haupt will give details upon request.