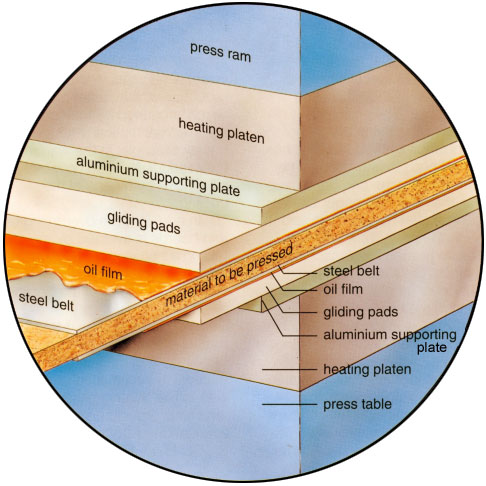

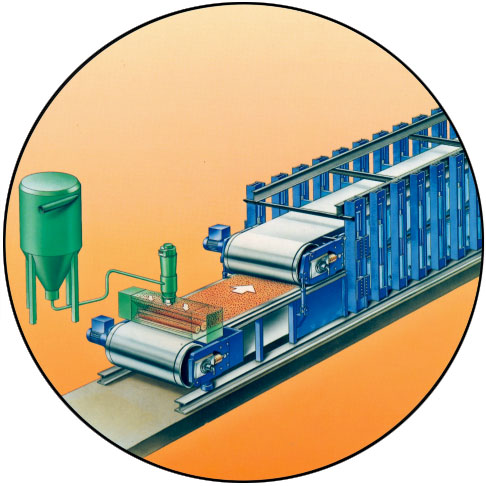

HYDRO-DYN PRESS TECHNIQUE

The characteristics of Hydro-Dyn press technique

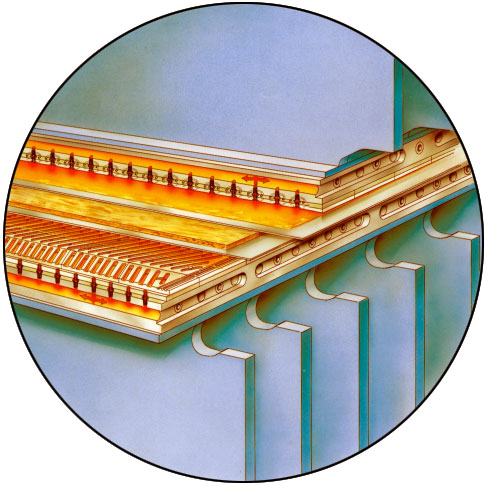

The HYDRO-DYN PRESS operates almost completely wear-free in the pressure zone, which ensures long lifetime of the steel belts. Low running costs, the high quality of the finished product and the reliability of the system make the HYDRO-DYN PRESS highly economic.

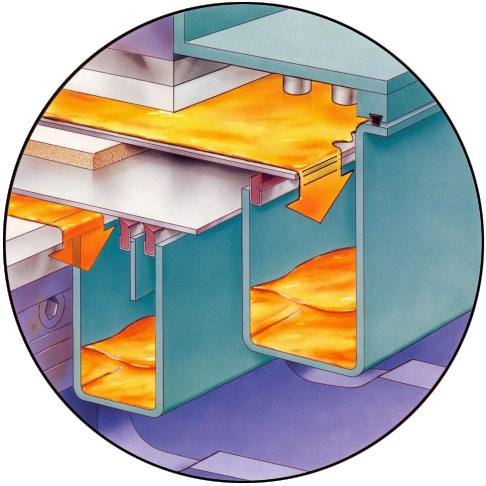

Another economic advantage of the HYDRO-DYN PRESS is that direct lamination, for example of wood based panels, has been executed – board production and the lamination are made in one operation. Low oil temperatures in the press’s cooling zone have solved certain problems which used to arise if synthetic materials have to be processed.

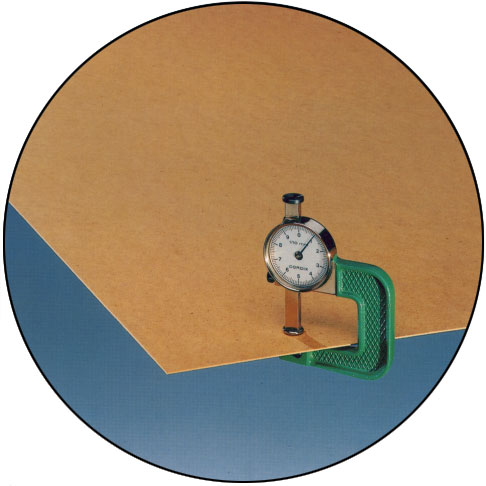

This use of a cooling zone also increases production capacity for wood based panels, and is the key-element for the production of thin boards of very high quality.

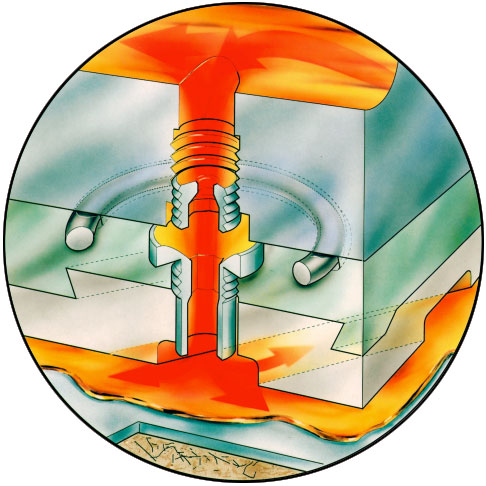

The technology on which the HYDRO-DYN PRESS is based represents an excellent combination of simplicity and funtionality. The oil on the steel belt serves a number of purposes:

- pressure transmission

- heat transmission during the heating up process

- heat transmission during the cooling down process

- lubrication

Optional:

By means of side belts the processing of raw materials having a liquid phase during the press operation has been solved.

The HYDRO-DYN PRESS presses continuously with an oil-lubricated sliding steel belt. This system offers the great advantage in providing area-pressure, which contrasts with other systems using chains, rollers, bars etc. providing line-pressure. The HYDRO-DYN PRESS SYSTEM provides minimum pressure- and temperature-deviations.